Start » About PREFORM » Gypsum foam

Gypsum foam as a natural and patented sound absorber

PREFORM is the only acoustics manufacturer to produce its own acoustic filler material – for over 30 years now. In addition to excellent room acoustics, our patented gypsum foam also offers a range of benefits in terms of absorption, insulation and environmental compatibility. The pros of this unique material for ceiling absorbers, wall absorbers, partitions and our room-in-room systems include:

- Effective sound insulation and sound absorption – Broadband absorbers

- Effective climate regulation through absorption and release of humidity

- Completely odourless

- Free of harmful substances, recyclable and sustainably produced

- Flame retardant (building material class B1)

Effective absorption

Gypsum foam has excellent absorption values even at low thickness. The material converts incident sound waves into thermal energy, absorbing them before the sound can spread in the room. In addition, the absorption coefficient can be adjusted during the production of the panels to achieve the ideal room acoustics for your individual needs.

Specially developed and patented for the office

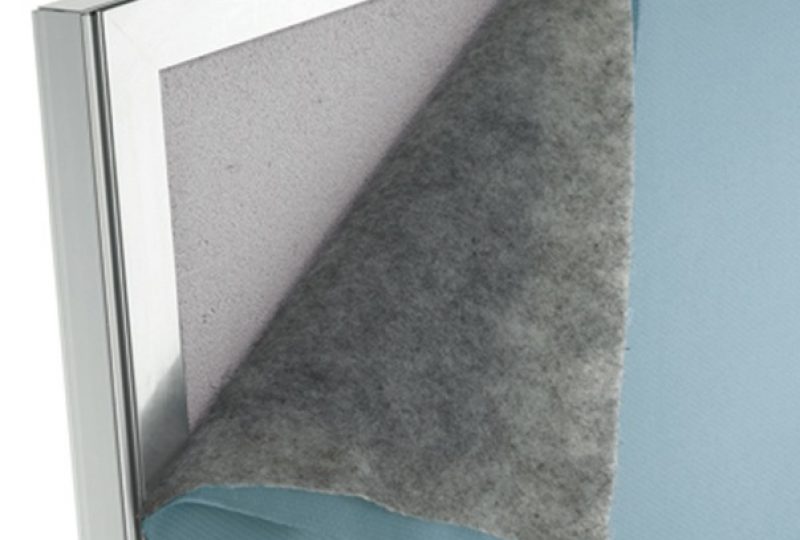

Gypsum foam consists of natural lime which is foamed with a polymer and processed into foam boards. Due to the open-cell pore structure, these gypsum foam boards offer extreme stability and maximum sound absorption.

In contrast to plastics, the production of gypsum foam involves no use of environmentally harmful CFCs.

Furthermore, our lime is extracted regionally, which has a positive effect on the CO2 footprint of our products.

Sound absorbers made of gypsum foam are also extremely lightweight, customizable and have heat-insulating properties, which makes them the perfect material when designing room acoustics in offices.

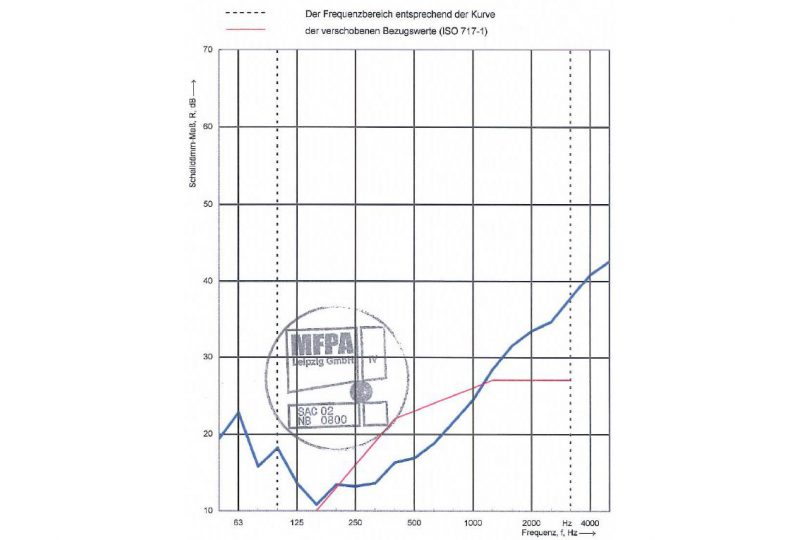

Measurable sound insulation at the workplace

Our patented gypsum foam is characterized by excellent absorption and sound insulation values. Sound is absorbed by the core material before it can spread. Individually adjustable, our sound absorbers can be cut to size according to the use of the room.

In this way, you achieve the right t room acoustics, perfectly adapted to your needs.

Would you like to receive a personal quote or further information? Then contact us today.

Sustainable materials produced in-house

Developed in collaboration with the Fraunhofer Institute for Building Physics, our gypsum foam combines innovation and pioneering research methods. The patented manufacturing process combines quality and sustainability in a unique way.

PREFORM is the only acoustics specialist in Europe that works 100% independently, from the production of the basic materials up to the installation.

Tailor-made, powerful and efficient

Production, consultation and design are fully vertically integrated under one roof. This enables us to respond quickly and specifically to our customer’s requests and to adapt all materials perfectly to their needs.

PREFORM (Schweiz) AG

Zunstrasse 11

CH-8152 Opfikon

PREFORM GmbH

Esbacher Weg 15

D-91555 Feuchtwangen

PREFORM GmbH

Esbacher Weg 15

D-91555 Feuchtwangen